|

|

Max Punching Width 50 MM Automatic Single Hole Paper Drilling Machine Touch Screen Single Hole Paper Punching Machine Equipment

|

|

Szczegóły Produktu:

Zapłata:

|

| Numer modelu: | NC500A | Przedmiot: | Inteligentna wiertarka do papieru ze sterowaniem programowym |

|---|---|---|---|

| Ilość głowicy wiertniczej (wrzeciona).: | 1 | maksymalna głębokość wiercenia: | 50 mm |

| Średnica otworu: | 3,0-8,0 mm | Szerokość karmienia: | 430 mm |

| Zakres marginesu tylnego miernika: | 6-36 mm (automatyczne) | Tryb wiercenia: | Automatyczny |

| Struktura: | Stała głowica wiertarska + ruchoma płyta | Odległość otworu (wrzeciona).: | Kontrola programu |

| Rozmiar płyty roboczej: | 540*380mm | Wyświetlacz: | 7-calowy ekran dotykowy |

| Wymiar maszyny: | 75*69*127cm | Woltaż: | 220 V (110 V) ± 10%, 50 Hz (60 Hz) |

| Moc: | 1000 W. | Waga maszyny: | 160 kg |

| Podkreślić: | 50mm automatic paper punching machine,touch screen single hole puncher,automatic single hole drilling equipment |

||

Max Punching Width 50 MM Automatic Single Hole Paper Drilling Machine Touch Screen Single Hole Paper Punching Machine Equipment

NC500A Intelligent Program-Control Paper Drilling Machine detailed information:

| Model | NC500A |

| Item | Intelligent Program-Control Paper Drilling Machine |

|

Drill head(spindle) quantity |

1 |

|

Max drill depth |

50mm |

|

Hole diameter |

3.0-8.0mm |

|

Feeding width |

430mm |

|

Back gauge margin range |

6-36mm(Automatic) |

|

Drill mode |

Automatic |

|

Structure |

Fixed drill head+movable plate |

|

Hole(Spindle) distance |

program control |

|

Work plate size |

540*380mm |

|

Display |

7" touch screen |

|

Machine dimension |

75*69*127cm |

|

Voltage |

220V(110V)±10%,50HZ(60HZ) |

|

Power |

1000W |

| Machine weight | 160kg |

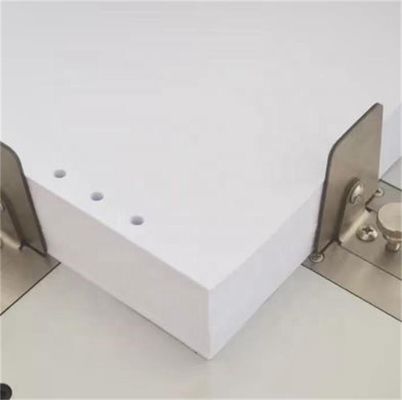

NC500A Intelligent Program-Control Paper Drilling Machine Specification:

Drill head(spindle) quantity:1

Max drill depth:50mm

Hole diameter:3.0-8.0mm

Feeding width:430mm

Back gauge margin range:6-36mm(Automatic)

Drill mode:Automatic

Structure:Fixed drill head+movable plate

Hole(Spindle) distance:program control

Work plate size:540*380mm

Display:7" touch screen

Machine dimension:75*69*127cm

Voltage:220V(110V)±10%,50HZ(60HZ)

Power:1000W

Machine weight:160kg

NC500A Intelligent Program-Control Paper Drilling Machine Main Feature:

Long-term high performance and absolute precision,The increased machine frame, the

high-precision guides and maintenance-free drives guarantee a long machine life.

The hole distance(X-axis) and back margin(Y-axis) can be set by program,Fixed spindle and

movable working plate to realize quick drilling of multi-hole and non-standard hole spacing.

Max stack height(drilling thickness) up to 50mm,drill diameter 3.0-8.0mm optional.

7" colorful touch screen,intelligent and easy to operate.

NC500A Intelligent Program-Control Paper Drilling Machine Drilling Tips:

Keep drill bits and spindles clean,clean drill bits after each usage and apply a light oil to the inside

& outside to avoid rust.

Set the drill bits correctly.Make sure that the drill shank is at the top end and fixed.

Change the position of the pad frequently,replace the drill bits and pads according to workload

requirement.

Store the drilling machine and drill bits in a dry and ventilated place.

Remember to empty the waste-paper box.

![]()

![]()

![]()

Dongguan Nanbo Mechanical equipment co., ltd have below advantage:

1. Various punching, binding and forming machines can be choosed.

2. Factory price with super quality.

3. Safe packing and fast shippment.

4. Excellent communication with best aftersales service.

![]()

About US

Our factory mainly produce two party of after printing products:

1:After-printing book equipment:double loop wire forming machine,double loop wire binding machine,semi-automatic punching machine, automatic punching machine,double loop wire binding &paper punching machine,Single loop forming spiral&binding machine,plastic spiral coil forming machine,plastic spiral coil binding machine,calendar hanger forming machine,book sewing machine,book folding machine. Mylar Tab Lamination Machine,Glue Perfect Binding Machine

2:Binding material: plastic spiral coil,double loop wire,nylon coated wire,Metal Spiral Coil .PVC filament, PVC Binding Cover,Calendar Hanger,Plastic Binding Comb

Our company advantages: we can supply after printing all kinds of full binding system:

1: first choose binding use double loop wire,our factory manufacture double loop wire forming machine and also manufacture

double loop wire,after you bought double wire binding machine from us,if you also buy double loop wire from us. the double loop wire can smoothly bind by our double wire binding machine,they can work and cooperate very successfully.

2: second choose binding use metal single spiral coil,it is more easy we have one machine forming metal single spiral coil

and binding notebook at the same time

3:third choose binding use plastic spiral coil,also very ok,we can manufacture plastic spiral coil forming machine and also plastic spiral coil binding machine.

Regards to our service:After you bought machine from us,if machine has any problem we can help you to solve it. after

you bought machine we will send a instruction book to tell you how to fix machine and operate the machine.if you have small

problem with machine tell us,we take a vidoe to show you how to solve,if big problem you can not deal with it,we will send master to your company help you to solve.Warmly welcome you call us

PS: We have many different kinds of machines, they are widely used for paper notebook binding, if you have any requrement please kindly email at tina@nanbobinding.com or wechat or whatsapp 008613431348359

Osoba kontaktowa: Tina Luo

Tel: +8613431348359

-

Łatwa konserwacja Automatyczna wykrawarka Ochrona bezpieczeństwa Łatwa regulacja

-

W pełni automatyczna wykrawarka o dużej prędkości Maksymalny rozmiar papieru 120x104 mm APM-420

-

Dziurkacz przemysłowy Grubość papieru 2 mm Do twardej okładki na notebooka

-

Automatyczna maszyna do dziurkowania papieru Maksymalna średnica papieru do dziurkowania 450x390 mm

-

Automatyczna maszyna do dziurkowania papieru, maszyna do dziurkowania o dużej wytrzymałości 1250 kg

-

80-120 razy / minutę Automatyczna maszyna do wykrawania drutu wiążącego Cewka grzebieniowa